Several Little Tricks to Achieve the Best Rosin Yield in Rosin Press

Posted by DABPRESS TEAM

Several Little Tricks to Achieve the Best Rosin Yield in Rosin Press

It has been just a little below 2 years since rosin was made known to the market. And within this period, this solvent-free distillate pneumatic rosin press technique has proved fairly practicable in the legal market, prompting a rush of innovative ideas in the wake of growing demand. Unlike other extracts, which exploit hefty equipment, solvents, and onerous processes to excerpt the resin, rosin manufacture involves only 2 mechanisms: heat and pressure. Rosin also by far requires lesser processing time, in some scenarios, yielding eatable produce in a few seconds.

The word “rosin” was initiated as a technique of creating a product needed to lubricate violin bows.

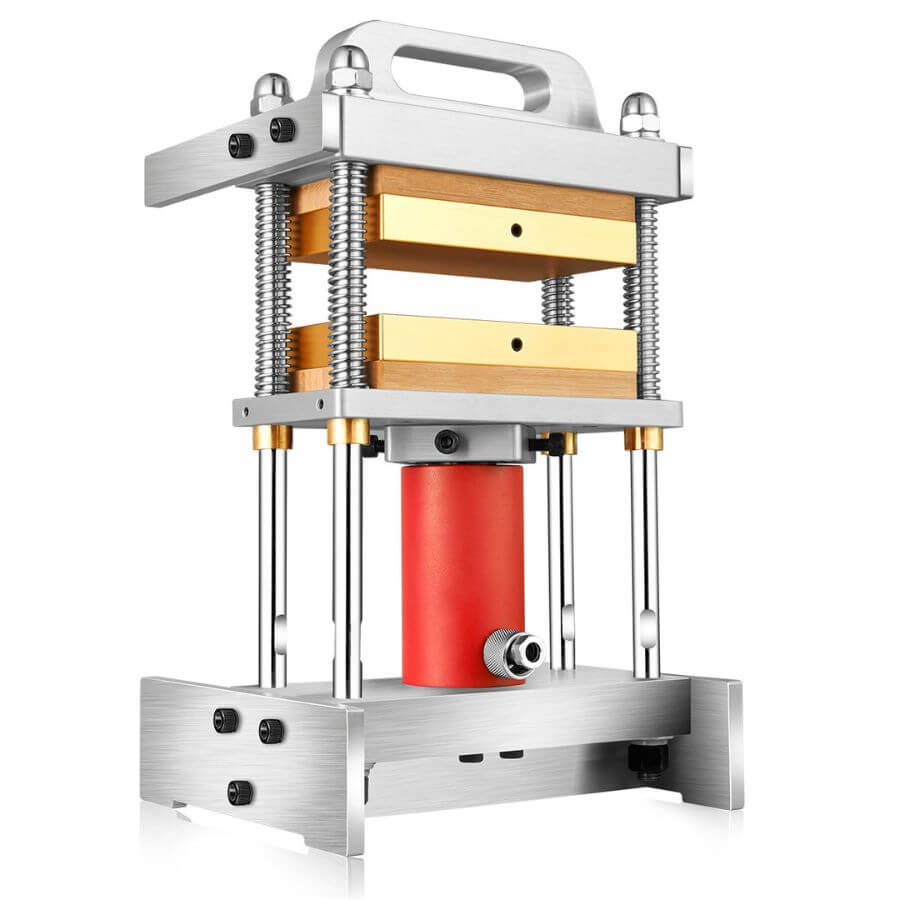

The rosin press kit is extremely handy in that it can what's more be used with rosin flowers. If implemented properly, the rosin press can challenge the potency, and yield of other extract products. Well, there are several little tricks to achieving the best rosin yield in rosin press and we have carried out a lot of trial and error in order to get the best tricks. When it comes to hydraulic rosin press and pneumatic rosin press, you can be sure we have based our wide-ranging research on them. Below are some of the little tricks you need to know in order to achieve the best rosin yield in the rosin press!

About the rosin Press Machine, We recommended Dabpress dp80 and dp100. Rosin dab machine dp80 $499 and dp100 $599 had been tested in the market for sale.

Additional Pressure Does Not Constantly Make a Difference

Numerous high-ton presses application is an absolute overload. We all can observe that the ideal pressure varies from 550 - 1,500 PSI at the plate, with maximum quality being on the lower end of that range. You can achieve yields over 24% with a rosin press at pressure as little as 550 PSI when pressing quality buds with appropriate moisture levels. This is one extremely challenging and debatable subject, if you are experienced with high pressures, certainly, keep it moving. We can only suggest maybe you try a lower setting and see what you get, as we have received countless results without going above the pressure usage.

Pick the Correct Rosin Micron Bag Filters

Above all, you can absolutely do rosin press without a bag if you so desire, but you are responsible for any little bits of material remaining on the other edge. If you are using a pneumatic rosin press or a rosin filter bag, obtaining the right micron screen size is crucial in order to attain a better yield-to-quality percentage. The rule to stick to is that you should keep the rosin press in anything less than or equal to the 90-micron width. Anything below this can affect your yield without getting visible gains in quality. Likewise, anything over 150-micron width has a tendency not to filter well, causing a decrease in quality. The connection between material and micron type is very significant, since the more the micron, the more permeable the mesh filter becomes.

Quality is Key, Trailed by Freshness

This may sound weird, but time after time, we always converse with clients who make use of rosin press and rosin plate kit about getting above-average outcomes. Virtually, it is always because they make use of an average pneumatic rosin press, which is seamlessly acceptable, but if you desire stellar outcomes, then it is essential to get stellar equipment. This does not imply you have to go buy a Certified Platinum rosin plate kit and other related equipment at your local store or fill it just with

just Glue, but with rosin, your outcomes are mostly determined if your resin press is up to par.

Having quality is also meticulously linked with freshness, and you would often get the very best outcomes when using a pneumatic rosin press. In the same way, we have not seen observable changes between the rosin press from coco, hydro, soil, etc. The growing media is among the factors to look out for inasmuch as the expertise of the grower is the major determinant of the individual substrate. That being said, certain strains and kinds of cannabis flowers have a tendency to produce more than others. When it gets down to this, the biggest determinant for flavor, quality, and yield, is all based on how sound and how strong the material is.

Relative Humidity Improves or Reduces Yields

Another key factor that we found after several rosin presses is that the relative humidity and moisture content often make a huge variance in your pneumatic rosin press yields. The cause of this is that if you have dry cannabis, it would act like a sponge when the trachomata are watery, thus saturated with rosin before it gets the opportunity to escape. Whenever you do rosin press, always ensure to keep the relative humidity content at least 55% to 62% for optimal results.

You can swiftly and simply check for moisture content by making use of either an analog hygrometer or a digital hygrometer. Although the digital hygrometer works more quickly and accurately, you can still make use of the analog hygrometer for your pneumatic rosin press. To raise the relative humidity, you can select pre-set humidity packs, it is that Easy!

Temperature Choice Based on Wanted Results

Nowadays, the temperature is conceivably the most discussed variable in the rosin press methods with serious supporters on both ends. Whenever you use heat and pressure, the speediness and constancy in which the trachoma liquefy are dependent mainly on what temperature is being used, as well as the uniformity of that heat distribution. Generally, there are two accepted ranges within which to press virtually any type of rosin.

- Cold Pressing (160°F to 190°F), pressed between one and six minutes or more, which often yields a better consistency.

- Hot Pressing (190°F to 220°F), pressed ranging from 50 seconds and three minutes, which often yields a very slick or shatter-like constancy.

In our opinion, the most successful rosin plate kit and pneumatic rosin press falls around the 210°F to 220°F range which proposes a greater concession between quality and yield. Anything above 235°F, however, there can be clear losses in flavor. Try and see what works best for you, if you find something great, let us know too!

CONCLUSION:

Whenever the rosin press is done from a top-quality pneumatic rosin press or rosin plate kit, is our complete desire to do it right. If there is anything to take away or keep from this article quality matters most. We hope you found our several little tricks to achieve the best rosin yield in the rosin press useful. Finally, the prospect is optimistic for the rosin press, rosin plate kit, and pneumatic press, and they will confidently continue to make waves in the business.